ASME B16.5 is a widely recognized standard that specifies the dimensions, materials, tolerances, marking, and testing requirements for pipe flanges and flanged fittings. These flanges are predominantly used in industries such as oil and gas, petrochemical, power generation, and marine engineering. The standard covers sizes ranging from 1/2" to 24" and includes pressure-temperature ratings, material specifications, and design considerations.

Key Features of ASME B16.5 Flanges

-

Size Range: ASME B16.5 flanges are available in nominal pipe sizes (NPS) from 1/2” to 24”.

-

Pressure Ratings: They are classified into pressure classes such as 150, 300, 400, 600, 900, 1500, and 2500, which determine their suitability for different operating conditions.

-

Material Types: These flanges are manufactured from various materials, including:

-

Carbon Steel

-

Stainless Steel

-

Alloy Steel

-

Nickel Alloys (e.g., Inconel, Monel)

-

Duplex and Super Duplex Stainless Steels

-

Types of ASME B16.5 Flanges

ASME B16.5 includes various flange types, each suited for specific applications:

-

Weld Neck Flange: Provides excellent strength and leak-proof connection for high-pressure and high-temperature applications.

-

Slip-On Flange: Easy to install and suitable for low-pressure systems.

-

Socket Weld Flange: Designed for small-diameter, high-pressure pipelines.

-

Threaded Flange: Ideal for non-welded systems, typically in low-pressure applications.

-

Blind Flange: Used to seal off a pipeline or vessel opening.

-

Lap Joint Flange: Paired with a stub end for applications requiring frequent dismantling.

-

Ring-Type Joint (RTJ) Flange: Equipped with a machined groove for metal-to-metal sealing, ideal for high-pressure systems.

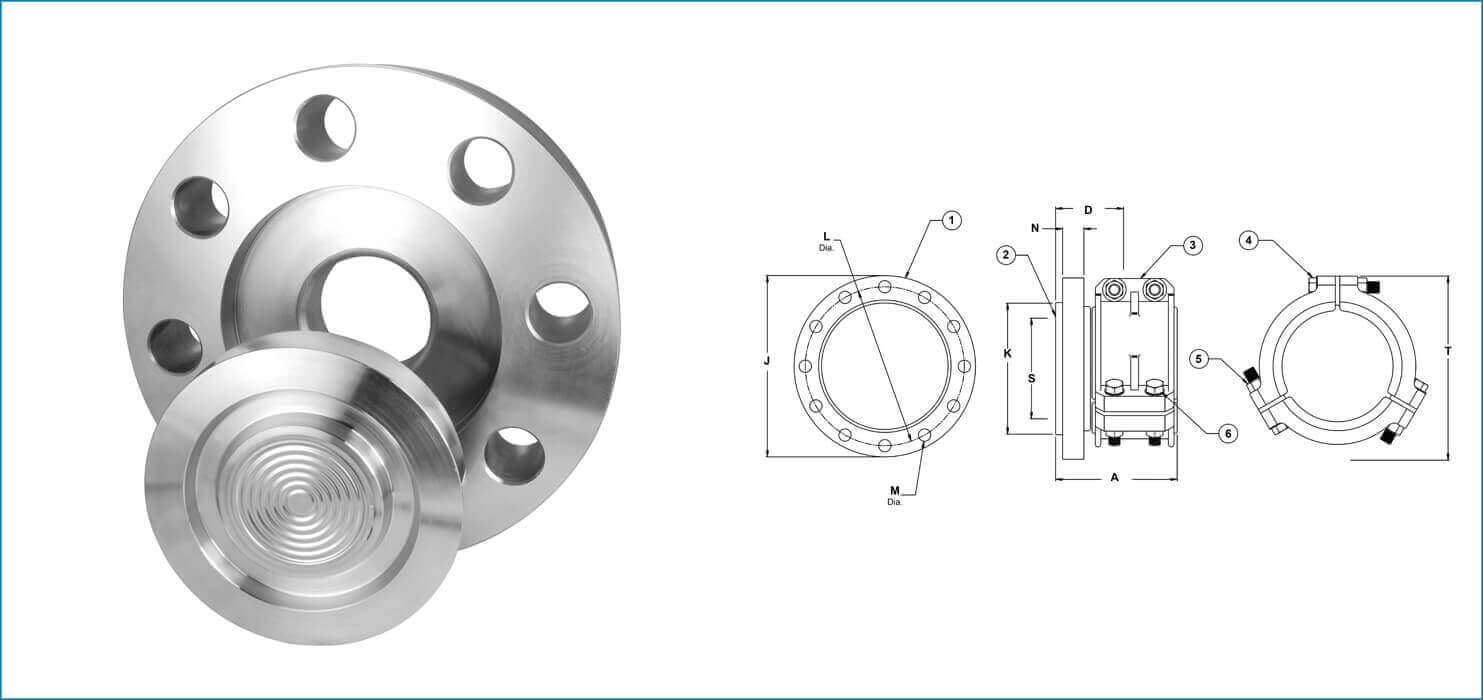

Dimensional Standards

ASME B16.5 flanges specify dimensions such as:

-

Outer Diameter (OD)

-

Bolt Circle Diameter (BCD)

-

Number and size of bolt holes

-

Raised face dimensions for sealing purposes

Pressure-Temperature Ratings

The performance of ASME B16.5 flanges under varying temperatures is determined by their material and pressure class. For instance:

-

Class 150 flanges have lower pressure handling capacity compared to Class 1500.

-

Material selection, such as stainless steel or alloy steel, can enhance resistance to extreme conditions.

Testing and Quality Assurance

ASME B16.5 flanges undergo rigorous testing to ensure reliability and compliance:

-

Hydrostatic Testing: Ensures pressure containment capabilities.

-

Non-Destructive Testing (NDT): Includes radiography, ultrasonic, and dye penetrant testing.

-

Dimensional Inspection: Verifies that the flanges meet specified tolerances.

-

Marking: Includes the flange material, size, pressure rating, and manufacturer’s details for traceability.

Applications of ASME B16.5 Flanges

-

Oil and Gas: Connecting pipelines and equipment in offshore platforms and refineries.

-

Petrochemical: Handling corrosive fluids and gases in chemical plants.

-

Power Generation: Steam and gas turbines, heat exchangers, and boilers.

-

Marine Engineering: Piping systems in ships and offshore installations.

Benefits of ASME B16.5 Flanges

-

High durability and strength for demanding applications.

-

Compatibility with a wide range of materials and pressure ratings.

-

Standardization ensures interchangeability and reliability.

-

Versatility in design for various operational needs.

ASME B16.5 flanges are integral components in modern piping systems. Their precise dimensions, robust materials, and adherence to stringent standards make them indispensable for industries requiring high-performance and reliable connections. Whether for high-pressure steam lines or corrosive chemical environments, ASME B16.5 flanges provide a dependable solution for diverse applications.

Comments on “asme b16.5 flanges in Qatar”